Krautreporter is a news service, run by journalists in Berlin. More than 16,000 subscribers pay a minimum of 5 Euros a month to get daily updates on the news and well-researched long-reads. Just like newspapers used to do.

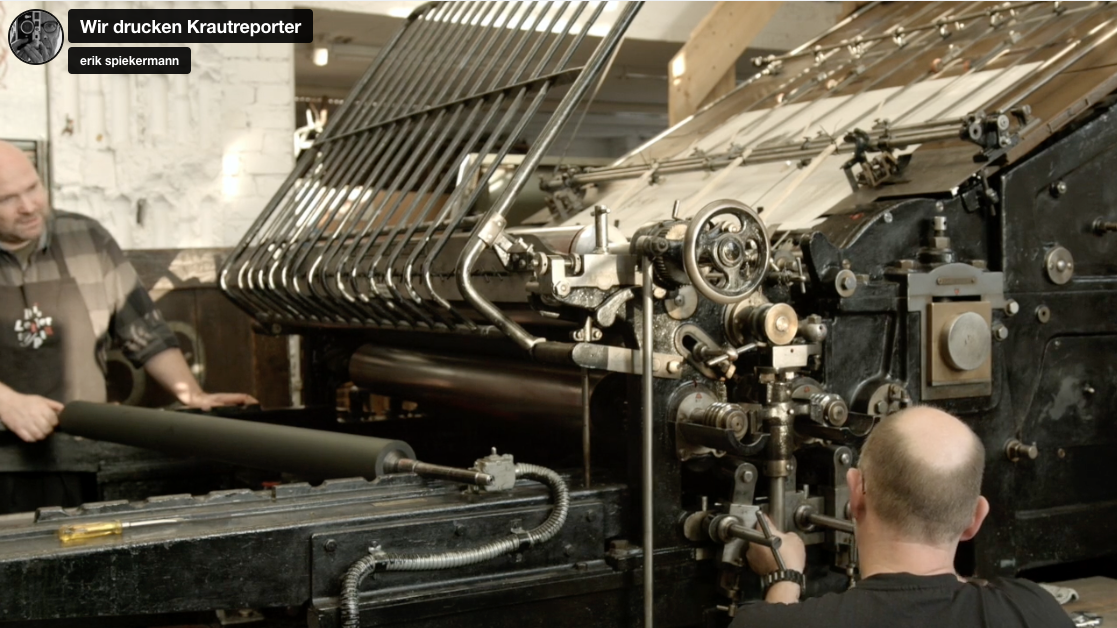

Printing a digital newspaper on a large Johannisberger press: video on Vimeo.

Once we had finished restoring our Johannisberger stop-cylinder press from 1924, we were looking for projects to test the machine. When I suggested to the friends at Krautreporter that perhaps we could print one special issue, they immediately went for that crazy idea.

We had already built our laser-setter and were able to make metal-backed plates up to 52 by 72 cm (approx 20×28in) directly from data, without going through photographic negatives. These plates fit our Heidelberg Cylinder press where we can print 8-up, i.e. 8 book-size pages on one plate. For the newspaper, however, we wanted to print the classic Nordic format, 44×57cm. In Germany we still have a few daily papers which are printed that size, the FAZ – Frankfurter Allgemeine Zeitung – being the most prestigious one.

Making four aluminium bases to get the thin plates to the height of metal type (23.56mm = 0.928in) was an adventure in itself. All the other things we didn’t know about this large press took us five months to figure out, but eventually we started to print. We had enough paper (60gsm newsprint) to print 6000 copies, 8 pages, all on one sheet, back and front, 88×114cm plus some trim. One side black only, the other black and red. 18,000 prints altogether, at a speed of not much more than 300 an hour, with 2 people at the press at all times. We ended up with almost 5000 good copies. The sheet was perforated in half inside the press but not separated. We wanted the readers to get the full effect – the exact opposite of a smartphone screen. For the mailing we folded the large sheet into a narrow strip with a label around it.

The movie shows our own Daniel Klotz at the press. His buddy Sebastian came to help whenever he could. Daniel spent more than half a year figuring out how to make everything work. Now we know why printers used to go through a three-year apprenticeship. That press wasn’t made to print from polymer plates, and it still holds a few secrets. But we have our proof of concept, a full-size newspaper. It is so popular with Krautreporter subscribers that we may have to print more issues.

***